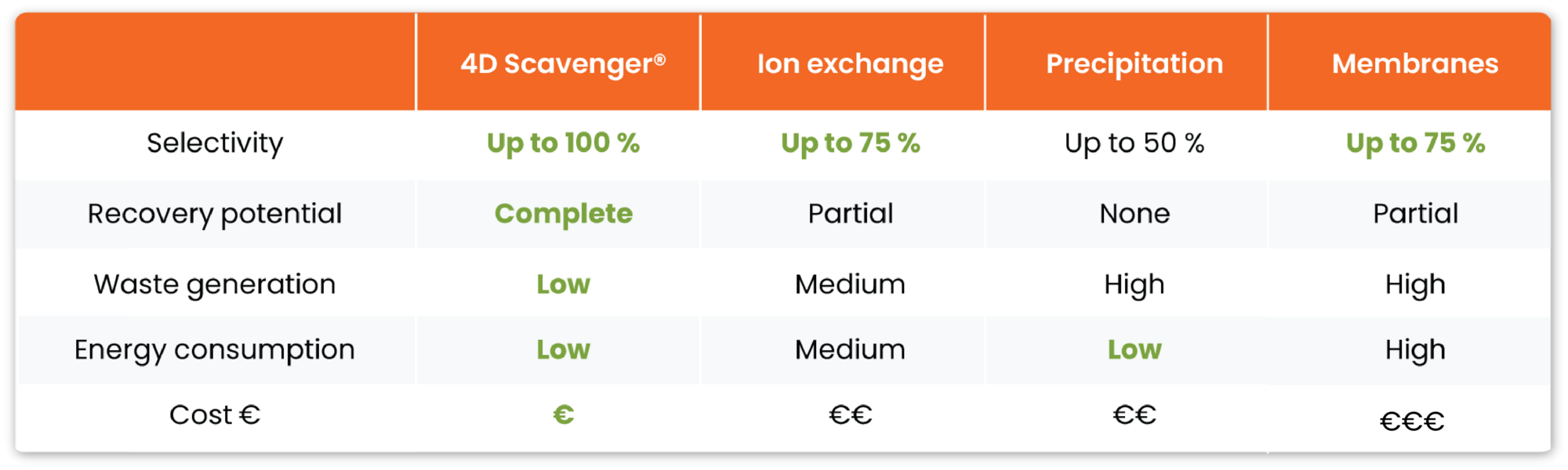

4D Scavenger® is a new metal recovery technology that has been designed to selectively recover dissolved raw materials from water and liquid solutions.

The unique technology presents unforeseen selectivity, compactness and efficiency which help to overcome even the most complex water treatment challenges. At best, it can prevent water pollution, reduce the need for virgin raw materials and enable closed loops in production cycles.

SELECTIVE

Our state-of-the-art technology is remarkably versatile by its nature, allowing us to modify its structural and functional design to target and extract specific components from mixtures of materials.

The selectivity presents substantial benefits as 4D Scavenger® can recover critical and high-demand raw materials with up to 100 % selectivity. Moreover, the concentrated raw materials are in many cases ready for reuse without further processing or refining.

COMPACT

EFFICIENT

4D Scavenger® technology is based on 3D-printed, chemically porous filters. The unique manufacturing method enables efficient recovery of even the smallest concentrations and introduces a more cost-effective way to process industrial waters.

This makes sustainable water treatment and recycling raw materials feasible for industries, companies, and processes where it was earlier restricted or not used at all.

Explore our products for more information or contact us.

We are happy to answer any questions you have!

Mikko Hänninen

Chief Executive Officer

+358 40 7053973

mikko.hanninen@weeefiner.fi

Elmeri Lahtinen

Chief Technology Officer

+358 40 559 2666

elmeri.lahtinen@weeefiner.fi

Timo Galkin

Business Director

+358 50 483 6440

timo.galkin@weeefiner.fi